Blaxernon 3, Kalamaria, P.C. 55133

T: 2310 455 537 E: info@lowedoors.com

Blaxernon 3, Kalamaria, P.C. 55133

T: 2310 455 537 E: info@lowedoors.com

Choose practical, safe and reliable solutions for the correct and efficient loading process for your industry.

In transport logistics the dock levelers are indispensable for fast loading and unloading. They are specifically designed to bridge the gap between the vehicle deck and the loading platform and at the same time level the difference in height between the ramp and the loading platform.

Dock shelters and seals protect goods and people against the elements and prevent drafts, they also save on energy cost even during the loading process. They meet a variety of needs and they can fit perfectly to any vehicle.

Loading houses are complete units incorporating dock levelers, dock shelters and seals and can be fitted in front of the existing buildings. They allow the storage area of the warehouse to be fully utilized while reducing construction costs.

DOCK LEVELERS

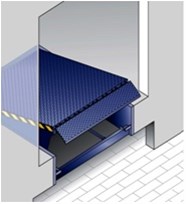

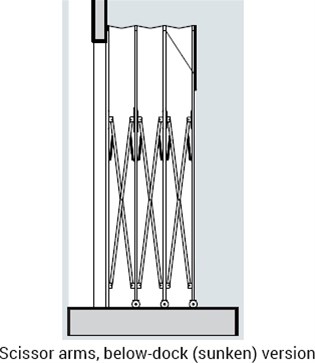

Dock levelers are well thought-out solutions for accurately leveling the difference in height between vehicle decks and loading platforms. In this way, the load can be driven into or out of the lorry with one single horizontal movement. The robust steel construction allows a high degree of twist, so vehicle loading can be easily accommodated even in the case of uneven loads. The reliable hydraulics with 2 lifting cylinders and one cylinder for the lip can cope with any situation, are easy and above all safe to operate. Because these dock levelers come with automatic emergency STOP valves integrated into the lifting cylinders, they lock the platform in an instant. This is particularly important in case a lorry departs prematurely while the platform is still loaded. The dock levelers are available in two categories:

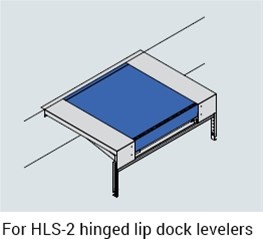

HLS-2 type with hinged lip:

The HLS-2 with a 405 mm long hinged lip represents the standard solution and is more than suitable for coping with the majority of loading situations. The practice-proven articulated steel construction can be supplied for a rated load of up to 180 kN. This type is characterized by the fast and safe start. The electro-hydraulic system brings the platform into the highest position and automatically extends the hinged lip. The button is released and the platform then lowers itself until the hinged lip rests on the vehicle deck. Loading and unloading can now take place safely and within the shortest possible time.

This type is also characterized by generously sized, particularly strong hinges. Thanks to their open design, the lip hinges cannot get clogged up with dirt, wood splinters or similar debris, and they provide high stability.

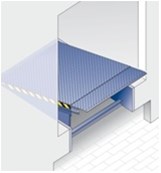

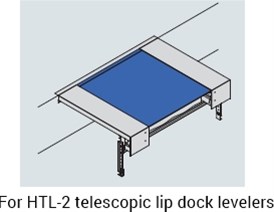

HTL-2 type with telescopic lip:

The HTL-2 dock leveler with telescopic lip is characterized by a choice of reach: 500 or 1000 mm. Continuous extension of the telescopic lip, which can be positioned with centimeter precision, allows maximum use of the loading platform.

The robust leveler in made of Sand blasted or stained, and coated with a 2-component PU paint. The standard carrying capability of do ck levelers is 60 kN but after request the rated loads can be up to 180 kN.

ck levelers is 60 kN but after request the rated loads can be up to 180 kN.

The telescopic lip is made of high-grade steel and has hinge strips. The especially stable front edge is completely reinforced and contains slits into which the beams are welded. Thus, the risk of damage to the telescopic lip due to improper use or incorrect bearing can be reduced to a minimum.

Also, the dock levelers can be placed in the internal space, to provide better insulation.

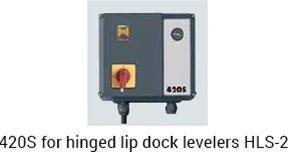

CONTROLS AND ACCESSORIES:

Control your dock levelers with the precision control panels from HORMANN. A sufficient solution with high resistance in external conditions and bumps, with infinite possibilities.

Multiple control systems: With possibilities such as indicator for errors and faults, service menu with maintenance, cycles and opening hours and connection facilities for accessories: proximity switch for door release function, wheel chock with sensor, signal lights, Photocell, warehouse light, driver registration.

DOCK SHELTERS

Dock shelters protect goods and people against the elements and prevent drafts, they also save on energy cost even during the loading process. The cladding at top and sides substrate of polyester threads and PVC-coated on both sides, which they are mounted on a galvanized, press-in frame, producing a stable, flexible and tear resistant construction.

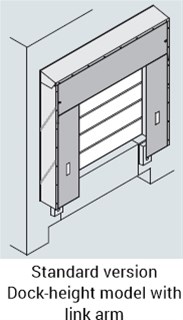

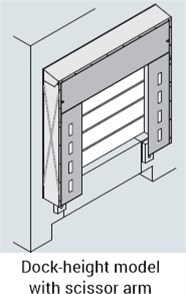

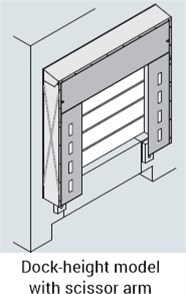

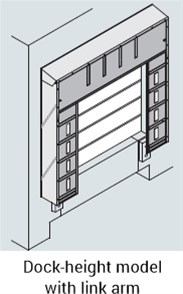

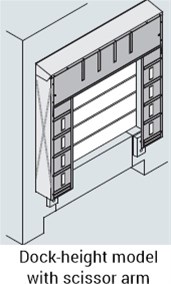

The dock shelters adapt to all sizes of vehicles and are therefore suitable for general use. An effective seal is always produced, even in the case of poorly reversed vehicles. This is due the construction of the arms, which connect the front and rear frames. They offer great flexibility, there by preventing collision damage.

Basic dock shelter type DS:

For higher traffic frequencies dock shelter type DT

Where loading takes place around the clock, DT dock shelters prove the ideal choice not least because of their particularly high-grade flap material. They are characterized by the durable product quality and minimal maintenance costs. Optionally for extra security and stability the dock shelters have corner seal cushions.

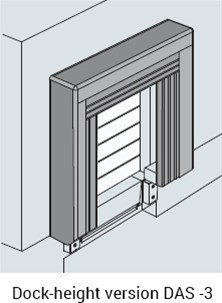

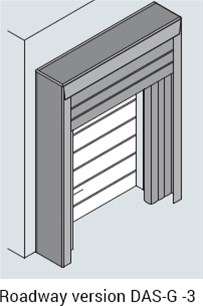

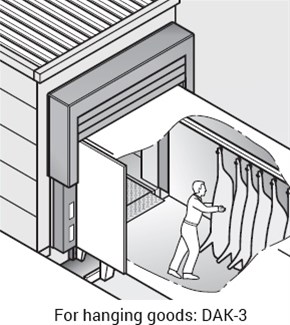

Inflatable dock seals type DAS-DAK:

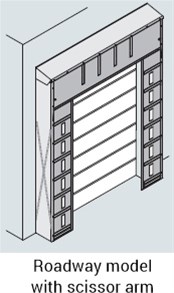

he DAS- DAK inflatable dock shelter is made of inflatable cushions with permanently elastic and high-frequency welded flap material. It, therefore, offers excellent sealing properties and for the most part prevents outdoor temperatures reaching the warehouse. Not until the vehicle has safely docked, is the dock shelter fan switched on, allowing the dock shelter to inflate around the vehicle and providing an airtight seal within seconds. Once loading has been completed and the fan is switched off, the cushions retract into the enclosure just as quickly via internally located tension cables and counterweights.When the cushions are deflated, the roadway versions allow vehicles to be driven straight into the warehouse unobstructed. The DAK-3 type is particularly recommended for hanging goods such as textiles or, for example, for transporting meat in refrigerated vehicles. Foam-filled side cushions provide the perfect seal at the sides. In the height, the opening remains completely free thanks to the inflatable top cushion in order to directly forward the goods on conveyor systems.

LOADING HOUSES

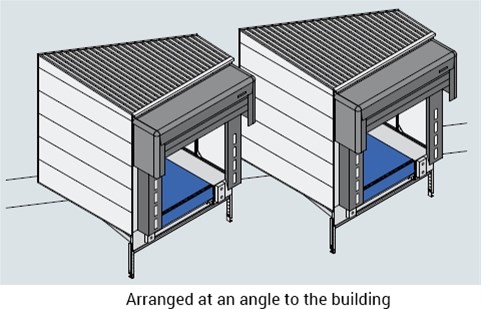

Loading houses are a complete and safe transfer unit that allow the storage area of the warehouse to be fully utilized while reducing construction costs. They are comprises pedestal with dock leveler, wall and ceiling cladding and opening for loading with dock shelter. They can be retrofitted in front of existing buildings, this means that warehouse space can be fully utilized right up to the outer walls. When carrying out alterations to the building or moving premises, the pedestals can be quickly dismantled and then re-assembled.

All the pedestals are made of special panel 'sandwich' type with PU-foam filling, offering great soundproof, good thermal insulation and safe loading.

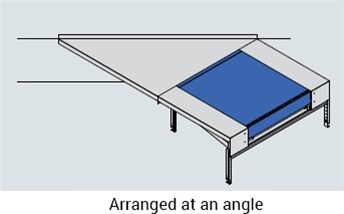

At the base of the loading house, you can choose the type of the dock leveler HLS-2 or HTL-2 and the arrangement position with the pedestal add-ons at an angle of 30°, 45° or 60° to the building in order to provide a wider range for maneuvering.

To download the catalogue for loading technology from the manufacture ΗΟΡΜΑΝΝ. Click Here.

To download the catalogue for dock levelers from the manufacture PEDANE. Click Here.

Subscribe to our newsletter and you will be the first that will know our offers!